What We Do

Welcome to Sara Green Energy

Sara Green Energy has made history by installing the first hydrogen production units in Portugal. These units use electrolysis to split water into hydrogen and oxygen, using electricity generated from solar and wind power. The hydrogen produced can be used for various applications, such as fuel cells, transportation, industry, and power generation. Sara Green Energy adheres to the highest industry standards and certifications, ensuring quality, safety, and reliability. The company follows the ISO 14687 specification for hydrogen fuel quality, and complies with all the local safety and environmental regulations in the countries where it operates. Sara Green Energy is committed to advancing the hydrogen economy and contributing to a greener future for the planet.

Our Corporate Mission

Innovative Leadership

We take pride in pioneering innovative solutions in renewable hydrogen production, setting industry standards, and leading the way in cutting-edge technology.

Environmental Stewardship

Our unwavering commitment to environmental responsibility drives us to minimize our carbon footprint and reduce the impact of our operations on the planet.

Customer-Centric Approach

We prioritize customer satisfaction and work tirelessly to meet and exceed their needs, ensuring they benefit from our sustainable hydrogen.

Global Impact

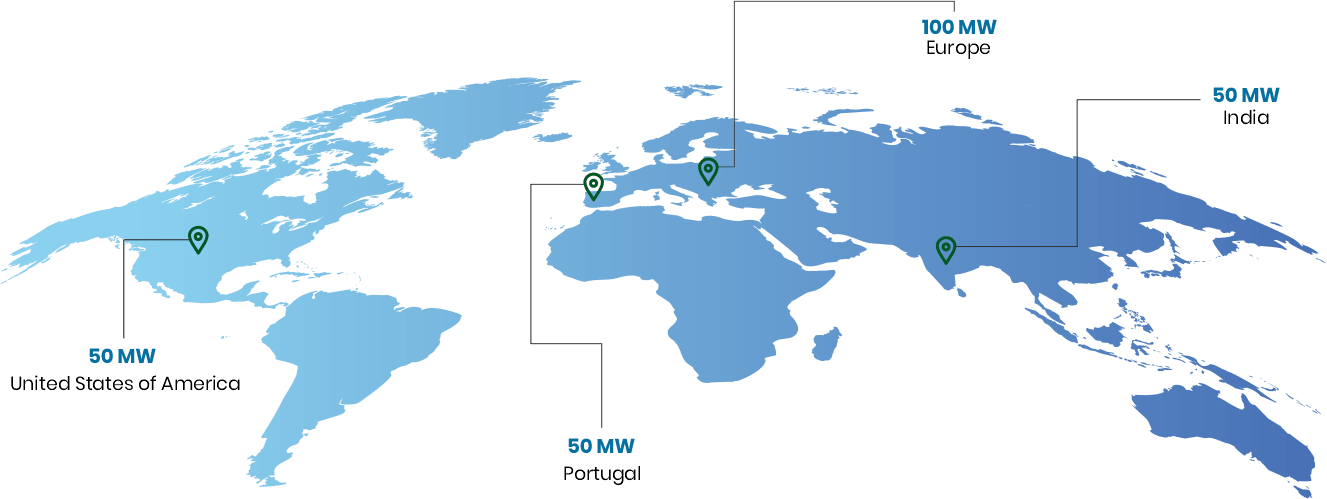

We aim to make a profound impact on a global scale by reducing carbon emissions and creating a more sustainable world for current and future generations.

Reliability

Our dedication to excellence ensures that we consistently deliver clean, reliable, and affordable H2 to meet the evergrowing energy demands of the world.

Sara Green Energy

Sara Green Energy

Business Lines and Differentiating Factors For Sara green Energy

Sara green Energy is a leading company in the field of hydrogen production, using renewable energy sources to produce clean and sustainable hydrogen. Founded by Saurabh S. Mehta and Visweswar Prasad Maganty, two visionary entrepreneurs with a passion for green energy, Sara green Energy has made history by installing the first hydrogen production units in Portugal. These units use electrolysis to split water into hydrogen and oxygen, using electricity generated from solar and wind power. The hydrogen produced can be used for various applications.

Business Lines

Our focus is the production and distribution of green H2.and O2. Our operations will kick off in 2025. We will invest in Portugal and other countries.

H2 Certification

Our green H2 will adhere to the highest industry standards and certifications, ensuring quality, safety, and reliability:

ESG Performance

Our commitment to Environmental, Social, and Governance (ESG) principles underscores our dedication to sustainability and responsible business practices.

Our business model

Hydrogen is gaining prominence as a

clean energy carrier and has various

business models associated with its

production, distribution, and

utilization.

We offer 2 business models in the

hydrogen industry, as co-location

and centralized production.

Co-location model

Sãra Green Energy offers a long term agreement with fixed and variable components, receiving green electricity from its client, when applicable, and making the needed investment in the H2 production. This model leverages the synergies between hydrogen and oxygen production and the existing operations of the facility.

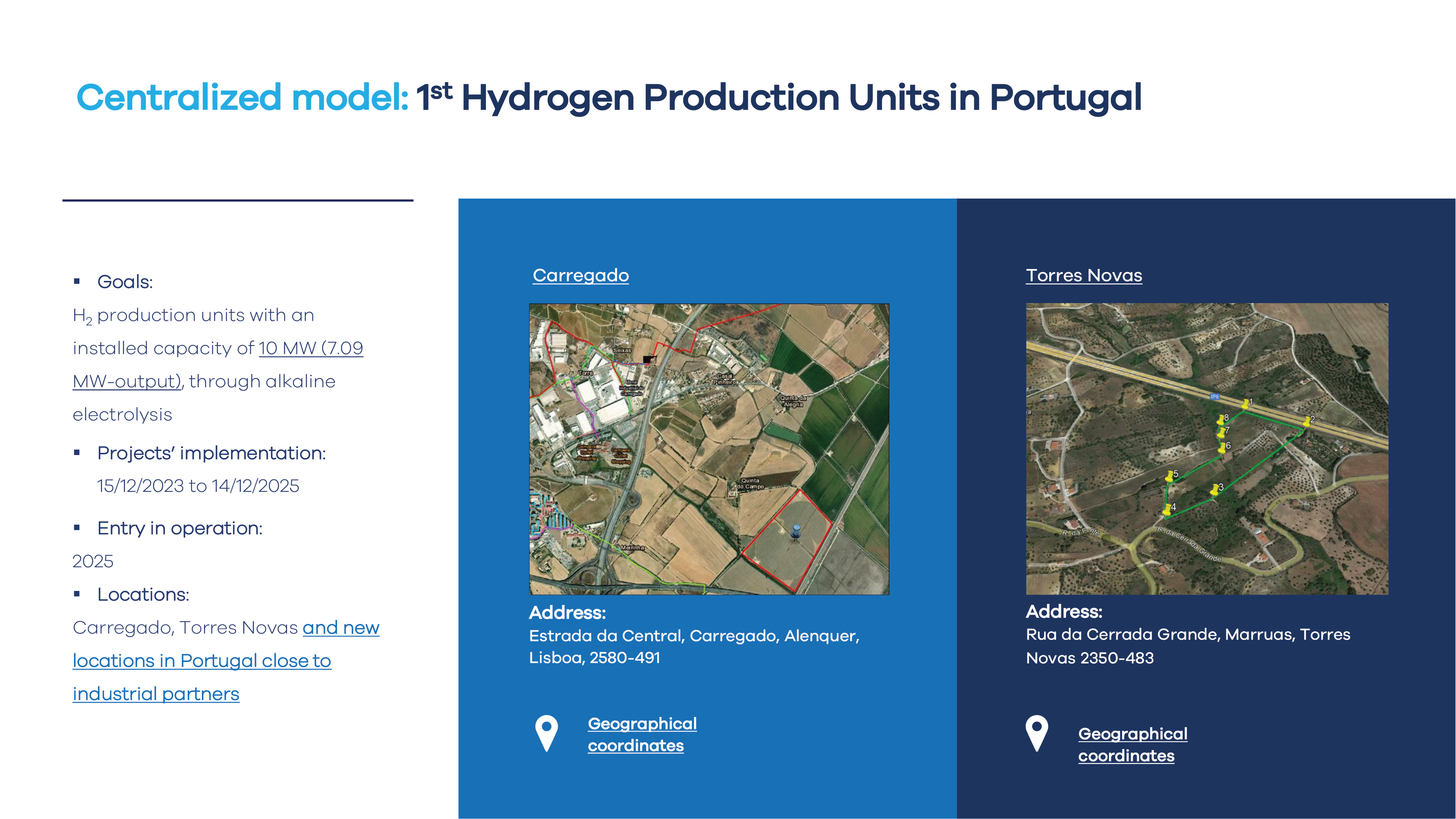

Centralized model

Sãra Green Energy will produce green hydrogen from a single location and distribute it through the portuguese grid, dedicated grid or using other transports. These centralized production plants are often designed to achieve economies of scale and produce H2 more efficiently.

1 st Hydrogen Production Units in Portugal

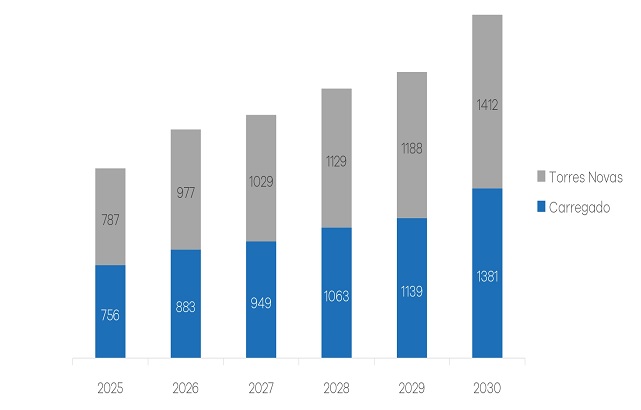

Green Hydrogen Production by industrial site (t), from 2025 to 2030

>4.000 t

Green hydrogen Carregado + Torres Novas + new locations

Production plant development is expected to start during the summer of 2025 to be able to achieve the mentioned goals.

Future Expansion (up to 2030)